Automotive Iso Certification

Target group of the training iso 26262 automotive.

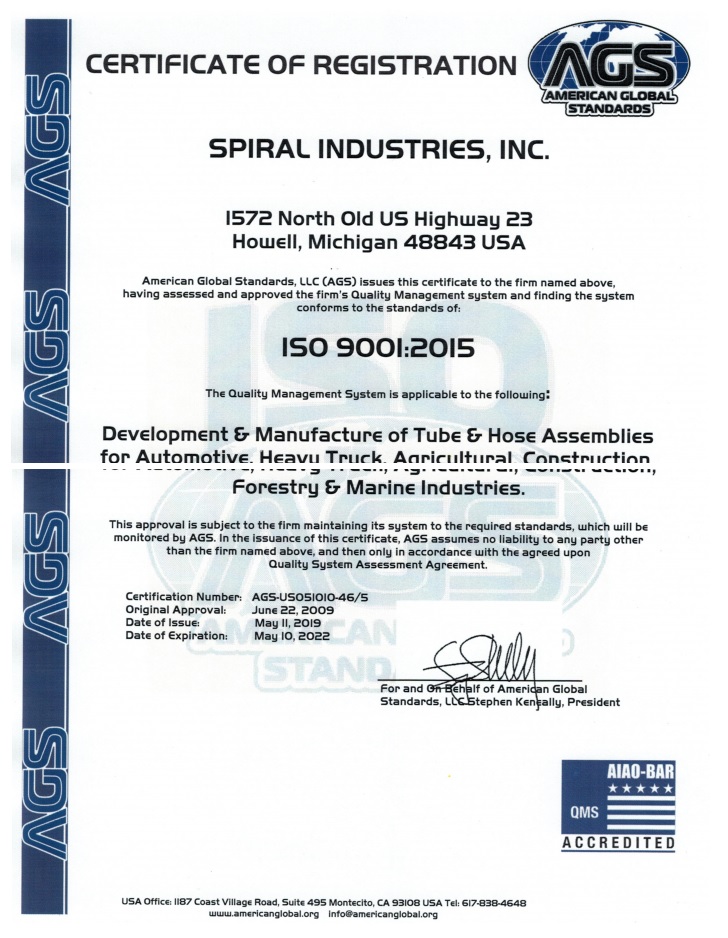

Automotive iso certification. The iso 9001 standard defines a framework for a quality management system. Ts 16949 was an internationally recognized quality management system specification for the automotive industry. Since iatf 16949 isnt designed to be a self sufficient quality standard but instead works best in conjunction with a comprehensive qms iso 9001 certification. Karen palmer discusses the rffs recent study of the new york isos carbon pricing proposal.

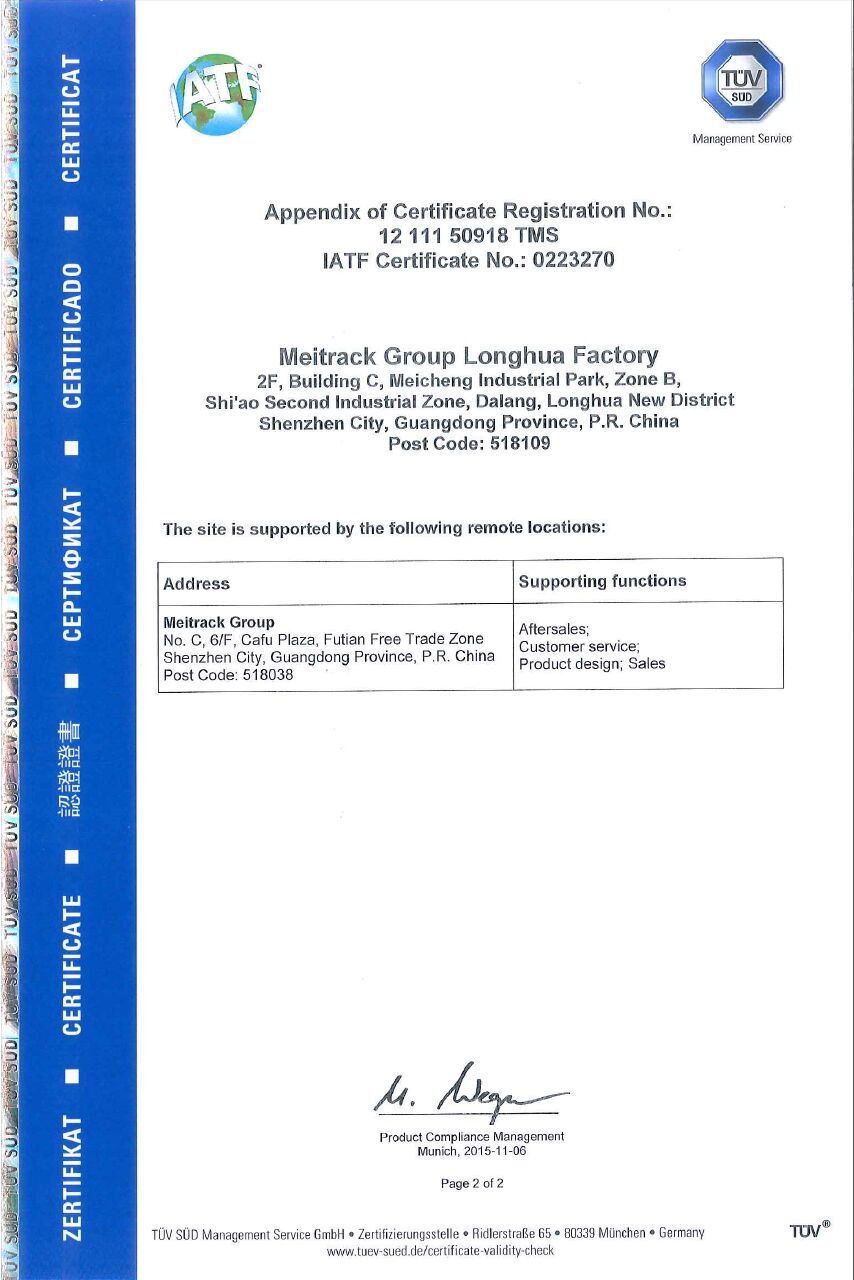

Iso 26262 automotive training based on our long standing practical experience in the field of functional safety and on our active membership of the relevant standards bodies we supply you with the necessary expertise in the standard iso 26262 designed specifically for the automotive industry. Isots 169492009 can be applied throughout the automotive supply chain. Certification takes place on the basis of the certification rules issued by the international automotive task force iatf. Most organizations manufacturing for the automotive industry are required to be certificated to iatf 16949 which was developed by the international automotive task force.

Based on iso 90012015 it was published in october 2016 and replaces isots 16949. In this episode of our power trends podcast resources for the futures rff dr. Iso 26262 is an international standard for functional safety in the automotive industry. The standard applies to electrical and electronic systems consisting of hardware and software components in vehicles.

The standard encompasses a number of principles including a strong customer focus support of top management the process approach and continual improvement. The isots 16949 can be applied throughout the supply chain in the automotive industry. Isots 16949 automotive industry quality management isots16949 is an iso technical specification aimed at the development of a quality management system that provides for continual improvement emphasizing defect prevention and the reduction of variation and waste in the supply chain.